When Richard French opened the doors of French Electrical fifty years ago in the Auckland suburb of Papatoetoe (then in the countryside!), electrical equipment was very different to what it is now. In those early days, the tools of the trade were heavy and rudimentary, a far cry from the high-tech, portable equipment that powers the industry today.

While reorganising the company’s storage room recently, Chris French, Richard’s son and the current owner of French Electrical, unearthed a shelf-load of dusty vintage equipment. Holding a well-worn clamp metre from the 1970s, Chris couldn’t help but marvel at how far the industry had come. “It’s amazing to think about all the circuits it’s tested and the problems it’s helped solve.”

As Chris sifted through the shelves, he found cloth-covered wires, ceramic fuses, and old equipment in worn leather cases. You can see pieces like these in the old French workshop image opposite in the 70s!

Each piece told a story of an era when the equipment was heavier and more basic than the lighter equipment with the digital readouts and smart diagnostics we have today. “These tools remind me of the countless hours Dad spent teaching me the trade,” Chris reflected. “They may be outdated now, but the principles of safety and quality workmanship they represent are timeless.”

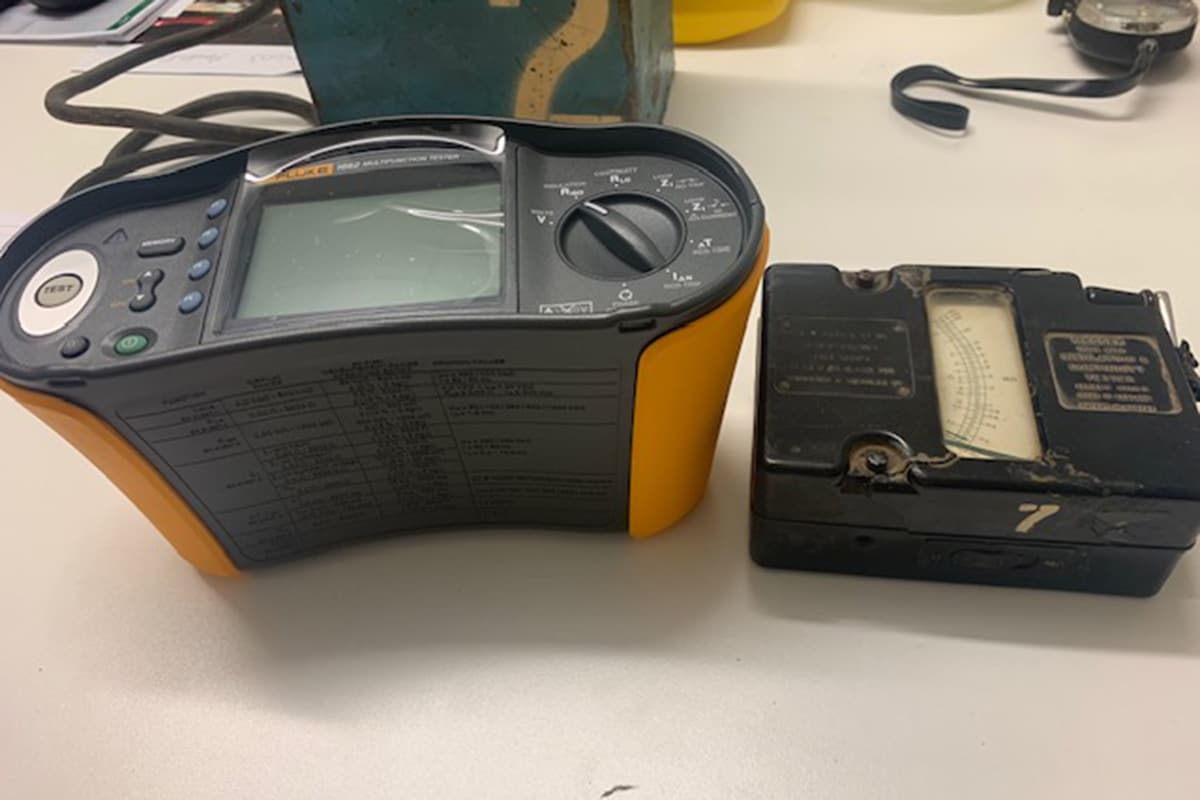

The images below make it easy to see the old and the new. The new equipment is brighter, perhaps to make it easy to find and to emphasise its safety function. In contrast, the older models are often in beautifully worked leather casing and made in a mix of glass and Bakelite, a popular thermosetting plastic from the mid-20th century known for its electrical insulating properties and heat resistance.

Have a read and enjoy the mix of new and vintage!

Clamp metres – the old workhorses and their modern equivalent

In the early days of electrical work, the clamp meter was a hefty piece of kit that wouldn’t look out of place today at Auckland’s Museum of Transport and Technology (MOTAT). These robust devices had one job: measuring current without interrupting the circuit. While revolutionary for their time, they were far from perfect. The leather cases, for instance, were less than ideal in wet conditions, absorbing water and steaming up the glass!

Despite their limitations, these tools were the pride and joy of many electricians. You can imagine a seasoned professional showing off their new “modern” clamp meter to their mates, marvelling at what was then cutting-edge technology.

Fast forward to today, and the clamp meter has evolved into something of a Swiss Army knife for electrical testing. Modern digital versions have expanded far beyond their original design, incorporating features that would have seemed like science fiction to earlier generations of electricians. They now boast Bluetooth and Wi-Fi capabilities, allowing real-time data sharing and remote monitoring. Built-in recording capabilities and software integration allow technicians to log measurements over time, enabling more comprehensive analysis.

These new models can also handle higher voltage and current readings, adapting to the increased power demands of contemporary electrical systems.

The old, heavy, isolation transformer and its lighter, modern equivalent

Fifty years ago, isolation transformers were the unsung heroes of electrical safety. Built like tanks and nearly as heavy, they weighed in at a back-breaking 10 kilograms. Many an apprentice electrician cut their teeth (and possibly strained their backs), lugging them from job to job. Despite their unwieldy size, these transformers were critical for protecting sensitive equipment and keeping users safe from electric shocks.

Nowadays, the landscape of electrical safety has transformed dramatically. The modern yellow power distribution unit, with its built-in circuit breakers and residual current devices (RCDs), looks futuristic compared to its blue predecessor. These new units are sleek, efficient, and packed with advanced technology that would have made electricians green with envy 50 years ago.

Where once we relied on hefty iron cores and thick copper windings to create electrical isolation through magnetic induction, we now harness the power of advanced electronics.

Yet, there’s something to be said for those old blue transformers. They may have been heavy, but they were reliable, sturdy, dependable blue boxes that kept us safe for many years.

Technology, functionality, and usability

With its sturdy casing and utilitarian design, the vintage Megger Insulation and Continuity Tester was once a stalwart of the electrical industry. Its time-worn casing and analogue dials tell tales of countless job sites and meticulous inspections. In contrast, the sleek, sunshine-yellow Fluke Multi-Function Tester is the face of modern electrical diagnostics.

Both these devices, separated by decades of innovation, share a common purpose: ensuring the safety and integrity of electrical systems. They’re an essential part of the electrician’s toolkit – identifying faults and ensuring that wiring and equipment meet stringent safety standards. The core principle remains unchanged – applying a test voltage to measure insulation resistance.

However, the similarities end there. The vintage Megger, with its hand-cranked operation, evokes images of a bygone era – you can almost hear the rhythmic clicking of the crank and see the swinging needle on the analogue gauge. The Fluke, by comparison, operates with silent efficiency, its digital display providing crystal-clear readings at the touch of a button.

The evolution from the Megger to the Fluke is not just about aesthetics or ease of use, it’s also about functionality. While the Megger excelled at basic insulation and continuity tests, the Fluke’s capabilities include RCD testing and data logging capabilities, allowing for more comprehensive analysis.

Moreover, the Fluke also comes equipped with modern safety features like automatic voltage detection and overload protection, safeguards that the designers of the original Megger could only dream of.

Today, French Electrical stands at the forefront of the industry – from smart home installations to solar panel systems, the company has evolved to meet the changing needs of a digital world. This journey from basic wiring to complex networks mirrors the growth of French Electrical itself. What started as a small family business, has transformed into a leader in electrical innovation, all while maintaining the personal touch and commitment to excellence that set it apart from the beginning.

As French Electrical continues to power homes and businesses into the future, it does so with a deep appreciation for its roots. The old equipment Chris discovered serves as a tangible reminder of how far they’ve come—and the enduring principles that will carry them forward.

Contact us here for any job, large or small. We do it all!