“Smart people learn from their mistakes. But the real sharp ones learn from the mistakes of others.”

Avondale Lifecare is a 67-bed rest home and hospital that offers dementia and medical care. After an electrical fire broke out, ambulance crews assessed more than 30 people, and two were taken to the hospital.

Fire and Emergency NZ were called to the Manukau Library and Research Centre due to an electrical fault that had caused a fire in the basement. The four-story building was heavily smoke-logged.

Proper electrical maintenance is important in your office or school, not just because of electrical fires. There are risks and hazards with electrical shock, equipment damage, disruptions and downtime, and compliance with safety regulations and standards.

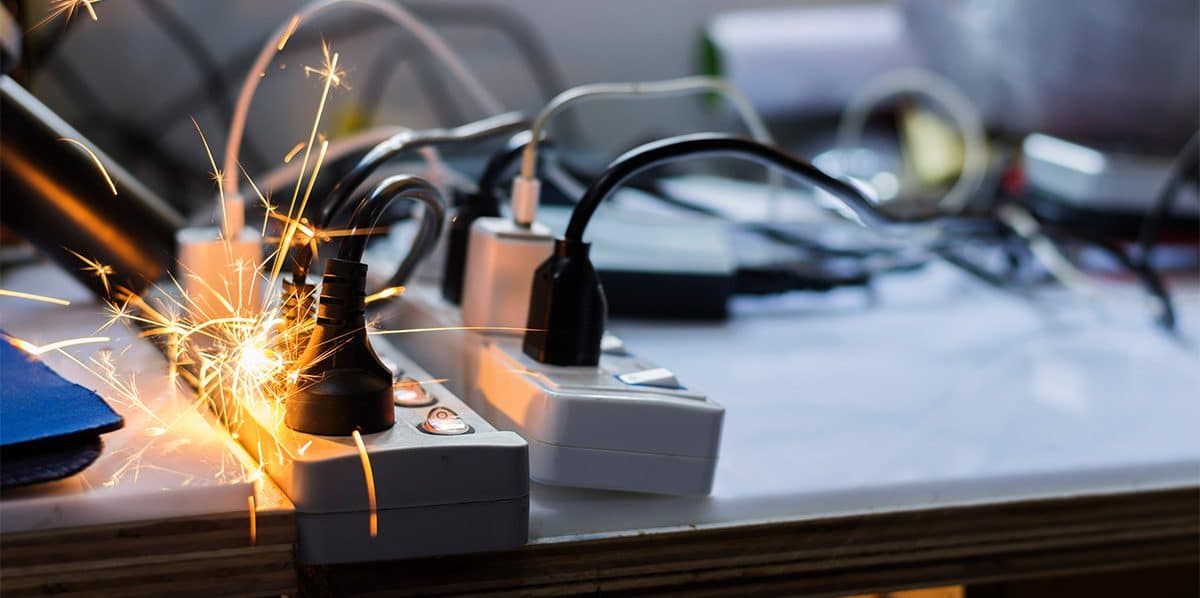

Quick tip: one thing to watch out for is overloading electrical power points—it is a fire hazard waiting to happen.

The most common technique employed by those who have had to learn from their mistakes? It’s called ‘run to failure’. Everything is operated continuously without any proactive maintenance interventions until it breaks down.

What are the basics of electrical maintenance?

Electrical maintenance in buildings would include:

- Regular inspections of electrical systems: wiring, outlets, switches, and appliances.

- Checking for overloading and usage of properly rated extension cords and multi-plugs.

- Maintain lighting systems; replace bulbs, clean fixtures, and ensure proper ventilation to prevent overheating.

- Switchboard maintenance and circuit breaker testing.

Of course, sites will vary in their requirements—air conditioning units, school bell, exterior lighting, security cameras, smart whiteboards, hand dryers, EV chargers, etc. If the premises have emergency lighting requirements, these maintenance checks should be completed twice a year. Read our article about building consent triggering emergency lighting updates.

Types of maintenance strategies

Run-to-failure maintenance operates equipment until it fails without proactive interventions. It is typically used for non-critical equipment with low repair costs or when preventive maintenance costs exceed repair expenses. Though seemingly cost-effective initially, it can result in unplanned downtime, shortened equipment lifespans, safety hazards, and higher repair costs over time.

Preventive maintenance entails scheduled inspections, servicing, and repairs to prevent equipment failures before they occur. Tasks are based on predetermined schedules or intervals—either time-based (e.g., monthly, quarterly) or usage-based (e.g., after specific operating hours). The goal is to extend equipment lifespan, minimise downtime, enhance reliability, and mitigate the risk of costly failures.

Predictive Maintenance utilises real-time monitoring of equipment condition and performance through techniques like sensors, data analytics, and predictive modelling. By analysing data trends, maintenance tasks are scheduled based on actual equipment conditions rather than fixed schedules. This reduces downtime, optimises maintenance schedules, improves equipment reliability, and provides cost savings by minimising unnecessary tasks.

Reliability-centered maintenance (RCM) is a systematic approach focused on maximising equipment reliability and minimising costs. It involves identifying critical assets, analysing failure modes, and developing customised maintenance strategies based on risk and reliability considerations. RCM prioritises maintenance tasks based on equipment criticality and potential failure modes, incorporating preventive, predictive, and proactive techniques to optimise maintenance efforts and resources.

How often?

The frequency of electrical maintenance in an office depends on various factors, including the building’s age, the condition of the electrical systems, and regulatory requirements.

Give us a call or book a consult, we’ll come and assess your property and provide you with a quote.